Below is an introduction to the main customers of ocean platform castings:

First major customer:

Nanjing High Precision Marine Equipment Co., Ltd

Nanjing High Precision Marine Equipment Co., Ltd. is a wholly-owned subsidiary of China High Speed Transmission Equipment Group (referred to as China Transmission), which can provide various transmission and propulsion equipment after the prime mover, including adjustable propellers, fixed pitch propellers, full rotation, side thrust, various marine main/auxiliary gearboxes, as well as various shaft rudder components and deck machinery.

As a national high-tech enterprise, the marine company has acquired a series of marine products with independent intellectual property rights through years of technology introduction and innovation, and is equipped with world-class production equipment. It has formed an annual design and production capacity of more than 1000 sets of marine products such as propellers and gearboxes. The company's design center is a provincial-level technology center with complete industrial design research and experimental conditions and infrastructure. It can provide thoughtful personalized design according to different ship types and requirements, thereby achieving environmental protection requirements of high product efficiency and low energy consumption. The marine products produced have been exported to overseas markets in large quantities, and the product quality meets European standards, winning high recognition from customers and partners.

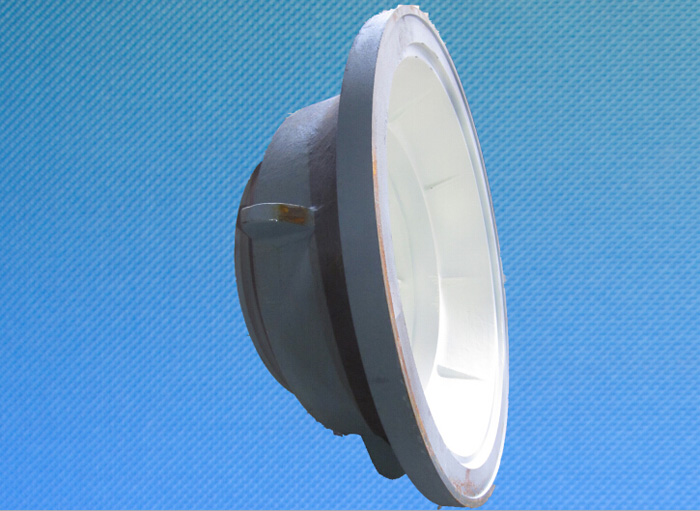

Since July 2013, our company has been in contact with Nanjing High Precision Marine Equipment Co., Ltd. regarding the "PT350 Climbing Machine Casting Project" and officially started production in October.

Second largest customer:

Zhengzhou Tianshi Offshore Oil Equipment Co., Ltd

Since June 2014, our company has been in contact with Zhengzhou Tianshi Offshore Oil Equipment Co., Ltd. regarding the "SJ220 Climbing Gear Casting Project". With the full assistance of Mr. Chen's leadership and employees from various departments, the production contract was officially signed in December 2014.

The ultimate client of the SJ220 Climbing Project is Guangxin Maritime Heavy Industry Co., Ltd., which is a joint-stock enterprise mainly engaged in the research and development of marine engineering equipment and special purpose ships, controlled and established by Guangdong Machinery Import and Export Co., Ltd. (GMG), a subsidiary of Guangdong Guangxin Holdings Group.

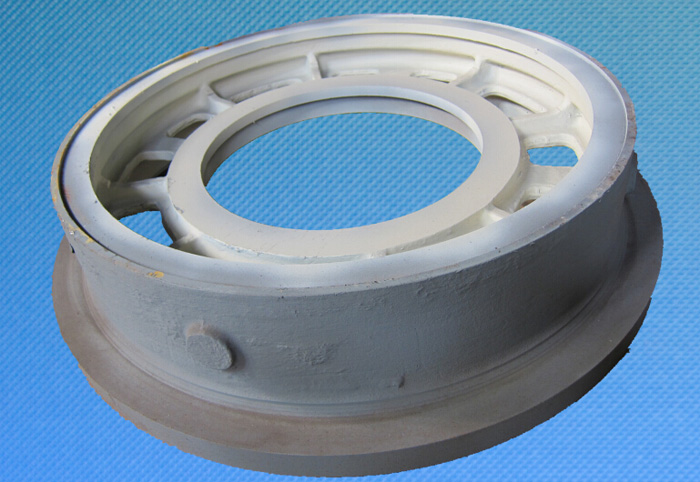

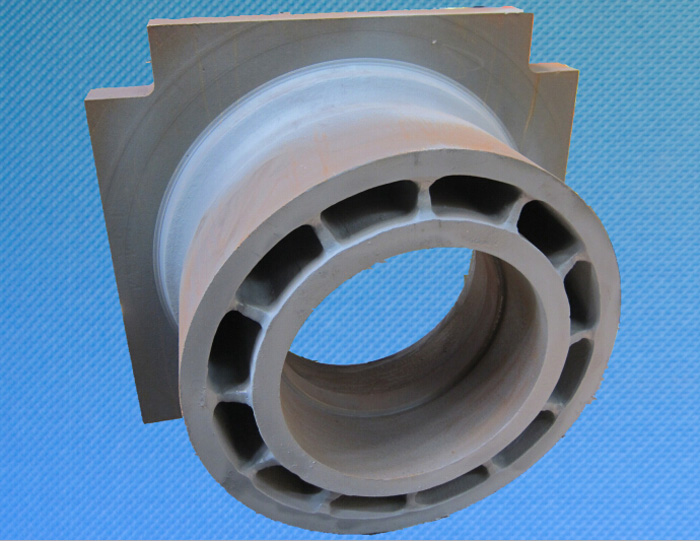

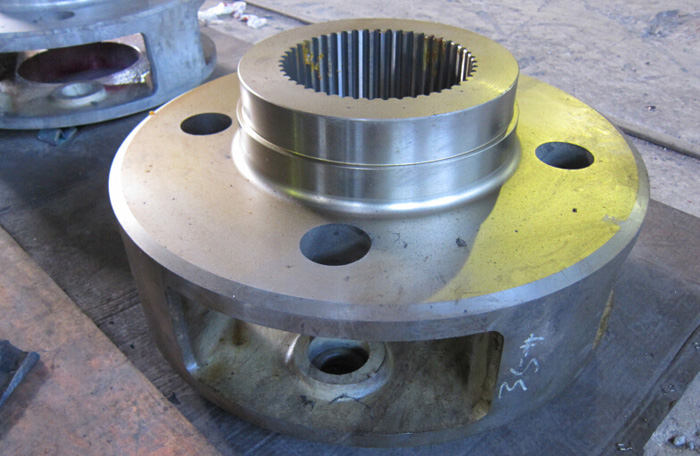

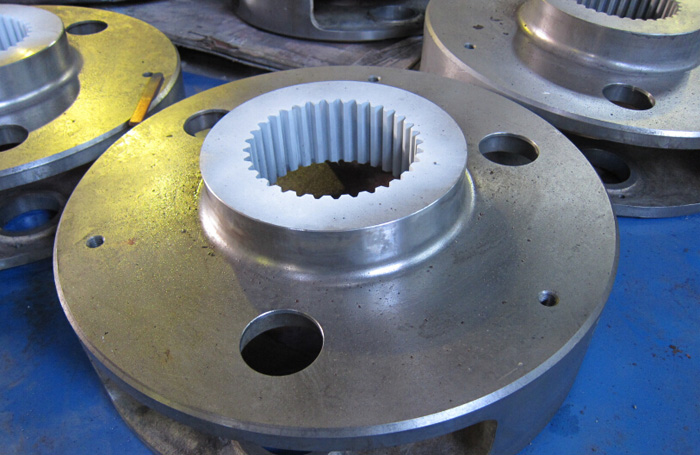

SJ220 Climbing Machine, Partial Design Parameters: Normal Jacking Load: 110MT; Design temperature: -20 to 55 ℃. The main products of SJ220 project castings are: Connecting Flang1-3, Bearing Pedestal, Climbing pinion shell, 1st stage planetary carrier, 2nd stage planetary carrier, totaling 7 varieties. In order to meet the design parameter requirements, Zhengzhou Tianshi Offshore Oil Equipment Co., Ltd. has put forward high technical requirements for SJ220 climbing gear castings: all procedures in the production process must comply with ABS specifications; 100% non-destructive testing of the casting surface, including UT for machined surfaces and MT or PT for non machined surfaces, with a testing level not lower than level 2.

Through the concerted efforts of all our employees, the first batch of castings was successfully delivered on January 31, 2015 and received recognition from the customer. In the following months, our company completed a total of 413 castings in the order. During this process, we encountered some difficulties, although some difficulties still exist, we firmly believe that with the joint efforts of our employees, we will overcome the difficulties and successfully complete the production of this batch of castings.

Third largest customer:

Qinchuan Machine Tool Group Co., Ltd

Qinchuan Machine Tool Group Co., Ltd. is a research and manufacturing base for precision CNC machine tools and complex tools in China. It is a leading enterprise in the Chinese machine tool industry and ranks third in scale. National high-tech enterprises and innovative pilot enterprises have established national enterprise technology centers, academician expert workstations, postdoctoral research workstations, American research and development institutions, and three provincial-level technology research and development centers. Has won one first prize of National Science and Technology Progress Award, four second prizes of National Science and Technology Progress Award, and one project recognition award of China Industry Award. Has been awarded honors such as "Leading Enterprise in the Industry in 2014", "Demonstration of Quality Benchmark Enterprise", "2013 Evaluation and Commendation of Chinese Industrial Enterprise Brand Competitiveness", "Shaanxi Province Enterprise Integrity Award", etc. The "Qinchuan QINCHUAN" trademark has been recognized as a "China Famous Trademark" by the Trademark Office of the State Administration for Industry and Commerce.

The main products include: gear grinders, thread grinders, cylindrical grinders (crankshaft grinders, spherical grinders, axle grinders), gear hobbing machines, universal CNC lathes and machining centers, gantry type turning milling boring grinding composite machining centers, plastic machinery (hollow machines, wood plastic equipment), precision and efficient lathes and other high-end CNC equipment, and CNC complex cutting tools; High end CNC systems, rolling function components, automotive parts, special gearboxes, robot joint reducers, screw rotor pairs, precision gears, precision instruments, precision castings and other component products; And modern manufacturing services such as digital workshop and system integration, machine tool remanufacturing and factory services, supply chain management, and financial leasing.

Since the beginning of 2015, our company has been in contact with Qinchuan Jiangsu Wind Power Branch regarding the "Offshore Platform Lifting Gearbox Casting Project", and officially started production at the end of April 2015. Thanks to our company's solid production foundation for offshore platform castings, this project was successfully completed, with a total of about 240 pieces.